At Tanfield Metal Spinners, metal polishing is not just an additional service; it is a specialised process designed to meet the highest quality and performance standards. With a fully automated metal polishing system in place, they can handle projects of all sizes, from individual bespoke components to large-scale production runs. Their process involves multiple stages, starting with rougher abrasives to remove surface imperfections, then followed by finer abrasives that deliver the desired finish without marking the metal.

One key factor that sets Tanfield Metal Spinners apart is their ability to adjust the polishing process according to the specific metal being worked. Whether it’s aluminium, copper, stainless steel, or brass, their experts understand the different properties of each material and how best to polish them for optimal results. The company also utilises a wide range of lubricants, such as kerosene, wax, and graphite, to enhance the polishing process and meet exact customer specifications.

Metal Spinning

Metal Spinning Bespoke Metal Spinning

Bespoke Metal Spinning Metal Polishing

Metal Polishing Machining

Machining Metal Pressing

Metal Pressing Metal Swaging

Metal Swaging Metal Fabrication & Welding

Metal Fabrication & Welding Precision Engineering

Precision Engineering Laser Cutting

Laser Cutting Inspection and Quality

Inspection and Quality Anodising, Electropolishing and Pickling & Passivating

Anodising, Electropolishing and Pickling & Passivating Agriculture

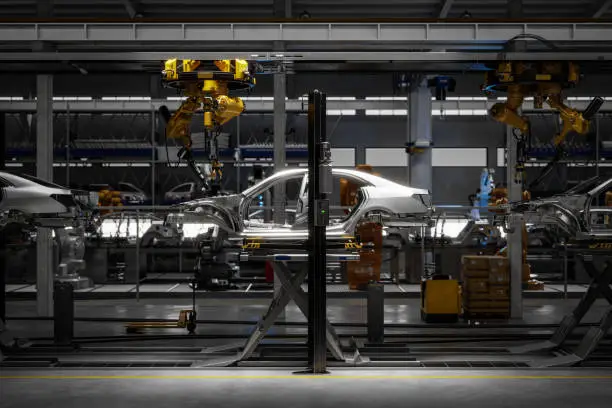

Agriculture Automotive

Automotive Air Movement

Air Movement Food Industry

Food Industry Marine

Marine Medical and Cryogenic

Medical and Cryogenic Playground

Playground Pressure Vessels

Pressure Vessels Renewable Energy

Renewable Energy Safety

Safety